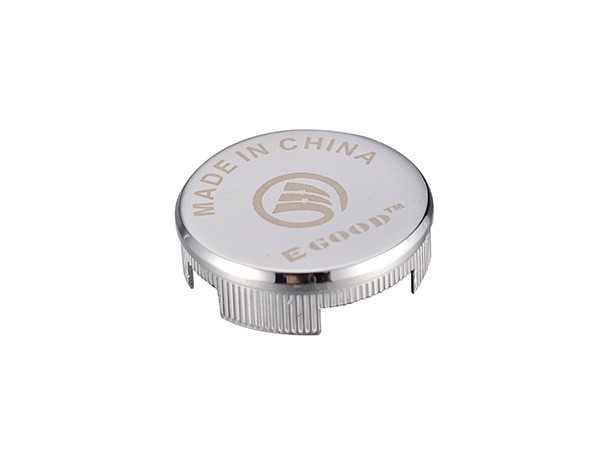

Cnc Machining Atomizer Metal Electronic Cigarettes Parts

Material: 6061 aluminum, environmentally friendly copper

Tolerance: +/-0.01mm Surface oxidation No burrs

Specifications: customized according to the requirements of drawings and samples

Introduction: Professional hardware accessories processing factory

Description

Technical Parameters

|

Material |

1. Aluminum: Al6061, Al6063, Al7075, Al2011, Al5052, etc. 2. Stainless Steel: SS303, SS304, SS316, SS420, 17-4, etc. 3. Steel: 12L14, 12L15, C45(AISI1045), etc. 4. Brass: C36000, C37000, C38000, etc. 5. Platic: POM, Delrin, Nylon, ABS, Teflon, PP, etc. |

|

Finish |

Plain, Polish, Brushing, Engraving, Screen-printing, Sandblast, Anodizing, Plating, QPQ, Oxidation, Power coating, Electrophoresis, Vibration grinding, Passivation, etc. |

|

Standard |

ISO, DIN, ANSI, JIS, BS and Non-standard. |

|

Certificate |

GB/T19001-2016/ISO9001:2015 GB/T24001-2016/ISO14001:2015 YY/T0287-2017/ISO13485:2016 It can match ROHS, SGS and environment protection |

|

Products Range |

Dia: 2-200mm or as your request |

|

Processing |

CNC milling, turning, drilling, tapping, grinding, etc. |

|

Tolerance |

+/-0.01mm or as per drawing request |

|

Inspection Tool |

CMM, Projector, Caliper, Micrometer, Thread gauge, Pin gauge, Altimeter, etc. |

|

Inspection |

1. First Article Report 2. In-process Inspection 3. Random Inspection 4. Final Inspection 5. Inspection Report & Material Certificate available |

|

Equipment |

CNC machining center, CNC lathe, Automatic lathe, EDM, CNC milling, Drilling machine, Centerless grinding machine, Cylindrical grinding machine, etc. |

|

Manufacturing Capability |

5-axis CNC milling machining centers (Brother), 6-axis CNC turning machines (Star, Tsugami), High precision grinding machines, Stamping machines, EDM, etc. |

|

Drawing Format |

PDF, Step, Igs, CAD, Solid, etc. |

|

Additional Service |

CAD Support; Design Assistance, Prototype Service, Low Volume Production, High Volumn Production, Assembly Service, Just-in-time delivery |

|

Application |

Electronics, Industrial equipment, Medical field, Auto industry, , Home appliance, etc. |

|

After-sales Service |

We will follow up every customer and solve all your problems after sale and make you satisfied. |

Q: How to get a quotation?

A: Please send us drawings in igs, dwg, step etc. together with detailed PDF.If you have any requirements, please note,

and we could provide professional advice for your reference.

Q. What if we do not have drawing?

A: Samples and drawings are available;

Of course, we would ensure the safety of the drawing.

Q: How long is your delivery time?

A: It would be 14-30 days normally for the parts to be ready and we had a system to ensure the time.

Q:How to ship? What about the packing details?

A: For small quantity, we have cooperation with TNT, FEDEX, UPS,DHL etc.

For big quantity, air or sea would be available for you to choose.

We attached our normal packing details.

If you have any special requirements, we would be willing to help.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the samples at an extra charge.

Q: What is your terms of payment ?How to pay?

A: 30% T/T in advance ,balance before shippment.If you have another questions, pls feel free to contact us ;

T/T,L/C ,Western Union,Paypalor as Customer's request.

News

How to process precision parts in thread

There are generally two types of feed for thread cutting when machining precision parts. One is the straight feed method and the other is the oblique feed method. When the thread profile depth and pitch are large, the tool can be fed multiple times. Cutting depth allocation methods are constant and decreasing.

1. When processing threads, only the X direction feed is used for each turning. The method of the left and right cutting edges of the thread turning tool participating in the cutting at the same time is called the straight feed method. Straight-line method programming is relatively simple, and it can obtain a more accurate tooth shape, which is often used for thread processing of thread pitch P<2mm and brittle materials.

2. When turning a thread with a large pitch, due to the deep thread groove, in order to smooth the rough turning, the method of simultaneous feed of two axes is called the oblique feed method. Straight threading is the simultaneous cutting of two cutting edges; oblique threading is single-edge cutting, which is not easy to pierce in turning, and a small surface roughness value can be obtained.

Precautions for thread turning

1. Generally, when cutting threads, the rough pitch to fine pitch are carried out at the same pitch. When the position encoder installed on the spindle detects the first rotation signal, it starts cutting. Therefore, even if cutting many times, the starting point of the cutting on the workpiece circumference of the precision part processing remains unchanged. However, from rough turning to finishing turning, the rotation speed of the main shaft must be constant. When the rotation speed of the main shaft changes, the thread cutting will produce disordered teeth.

2. Generally, due to the lag of the servo system, irregularities will appear in the thread lead at the beginning and end of thread cutting. In order to consider the thread accuracy of this part, when cutting the thread on the CNC lathe, it is necessary to set up the speed-increasing feed section and speed-reducing feed section. Therefore, in addition to the effective length L of the thread, the actual length of the processed thread should also include the length of the speed-up section and the speed-down section. Its value is related to the pitch and speed of the workpiece processed by the precision parts, which is set by each system and is generally greater than one guide. Cheng.

Hot Tags: cnc machining atomizer metal electronic cigarettes parts, China, manufacturers, suppliers, factory, wholesale, customized, made in China

Send Inquiry