Metal Components Manufacturing

Description

Technical Parameters

| Quick Detail |

|

CNC Machining or Not: |

Yes |

| Material Capabilities: | titanium,stainless steel, aluminium, copper, brass,Plastics |

| Micro Machining or Not: | Not Micro Machining |

| Place of Origin: | Guangdong, China |

| Drawing Format: | .pdf/.dwg/.igs./.stp/x_t. etc |

|

Product Scope: |

household appliances, office appliances, electronics, hardware, plastics, lighting, electronic cigarettes, atomizers, aviation, toys, sanitary ware, furniture, medical care, cars, sports equipment and machinery manufacturing industries. |

| Surface Treatment: | Galvanizing, anodizing, powder spraying, passivation, brushed polishing, sandblasting, electroplating, etc. |

| Services: | CNC machining, Milling, Turning, Grinding etc, and assembly |

| QC System: | 100% inspection before shipment, Third Party inspection available |

| Lead time: | 3-5 workdays for samples, 10-20 days for bulk order |

|

Shipment Terms: |

express,air freight,sea freight |

| Supply Ability: | 10000 Piece/Pieces per Month cnc machining automobile parts manufacturer |

| Packaging Details: | 1 PC per PE Foam for standard packing,or depanding on your requset for cnc machining automobile parts manufacturer |

| Port | FOB Shenzhen |

Metal components manufacturing plays a critical role in modern industrial processes and is an essential component in the production of a wide range of consumer and industrial products. This manufacturing process involves the creation of parts and components made of metals, which are used in a variety of applications across industries such as automotive, aerospace, defense, medical, and construction.

Metal components manufacturing involves several processes, including forging, machining, casting, stamping, and welding. Each of these processes utilizes diverse techniques and machinery to shape, mold or join metal parts into the desired form and size. For example, forging involves the heating of metallic materials such as steel, aluminum, or copper to make them more pliable and easier to shape using a hammer or press. Machining involves the use of lathes, drills, grinders, and other cutting and shaping tools to produce complex shapes and designs on metal parts.

Casting, on the other hand, involves the heating of metal materials to a molten state and then pouring it into a mold to form a specific component. Stamping is a manufacturing process that involves the use of a press machine to create parts by cutting, bending, and shaping metal sheets. Welding is a joining process that involves the use of heat to melt and fuse two or more metal parts together.

Metal components manufacturing requires specialized skills and knowledge, and the use of advanced equipment and techniques to produce high-quality components that meet the required specifications. Manufacturers must carefully select the appropriate materials, processes, and equipment to ensure consistency and precision in producing parts at scale. Metal components are an integral part of many industrial processes, and their reliability and durability are essential in ensuring the safety and efficiency of these processes.

In conclusion, metal components manufacturing plays a critical role in modern industrial processes and is essential for the production of a wide range of consumer and industrial products. This manufacturing process involves several techniques and processes that require specialized knowledge and skills, and the use of advanced equipment and technology. Metal component manufacturers must ensure the reliability and durability of their components to ensure the safety and efficiency of industrial processes.

|

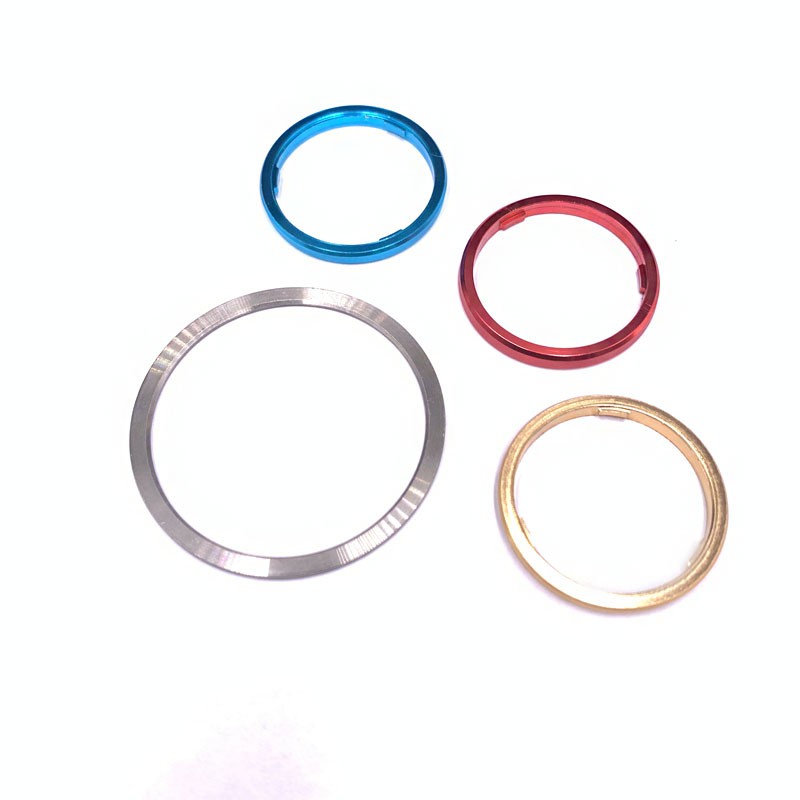

Product Show

|

| Other Products |

Q&F

1. Q.What 's your payment terms?

T/T,L/C at sight,Western Union

2. Q.How can we get your price ?

We need below information to quote for you:

1. Product Name

2.Standard

3. Material Grade(Chemical Composition)

4.Dimension

5. Quantity

6. The Drawing for Special Parts

| Contact Us |

![]() sales03@pride-cnc.com

sales03@pride-cnc.com

![]() Block D, Dianlian Science Park, Matian St., Guangming District, Shenzhen 518106, China

Block D, Dianlian Science Park, Matian St., Guangming District, Shenzhen 518106, China

![]() +8615915705962

+8615915705962

![]() 15915705962

15915705962

| Our Equipment |

|

Latest News |

The case ordered by Germany from us requires an internal roughness of Ra1.6 frame with an R angle of 0.25, and an external roughness of 0.6. The height requires us to have no scratches. If there are scratches, we will return all the products. Requirements, customers and our stable cooperation

Hot Tags: metal components manufacturing, China, manufacturers, suppliers, factory, wholesale, customized, made in China

Previous

Metal Parts FabricationSend Inquiry