CNC Aluminium Machining 4 Axis Mechanical Components

Description

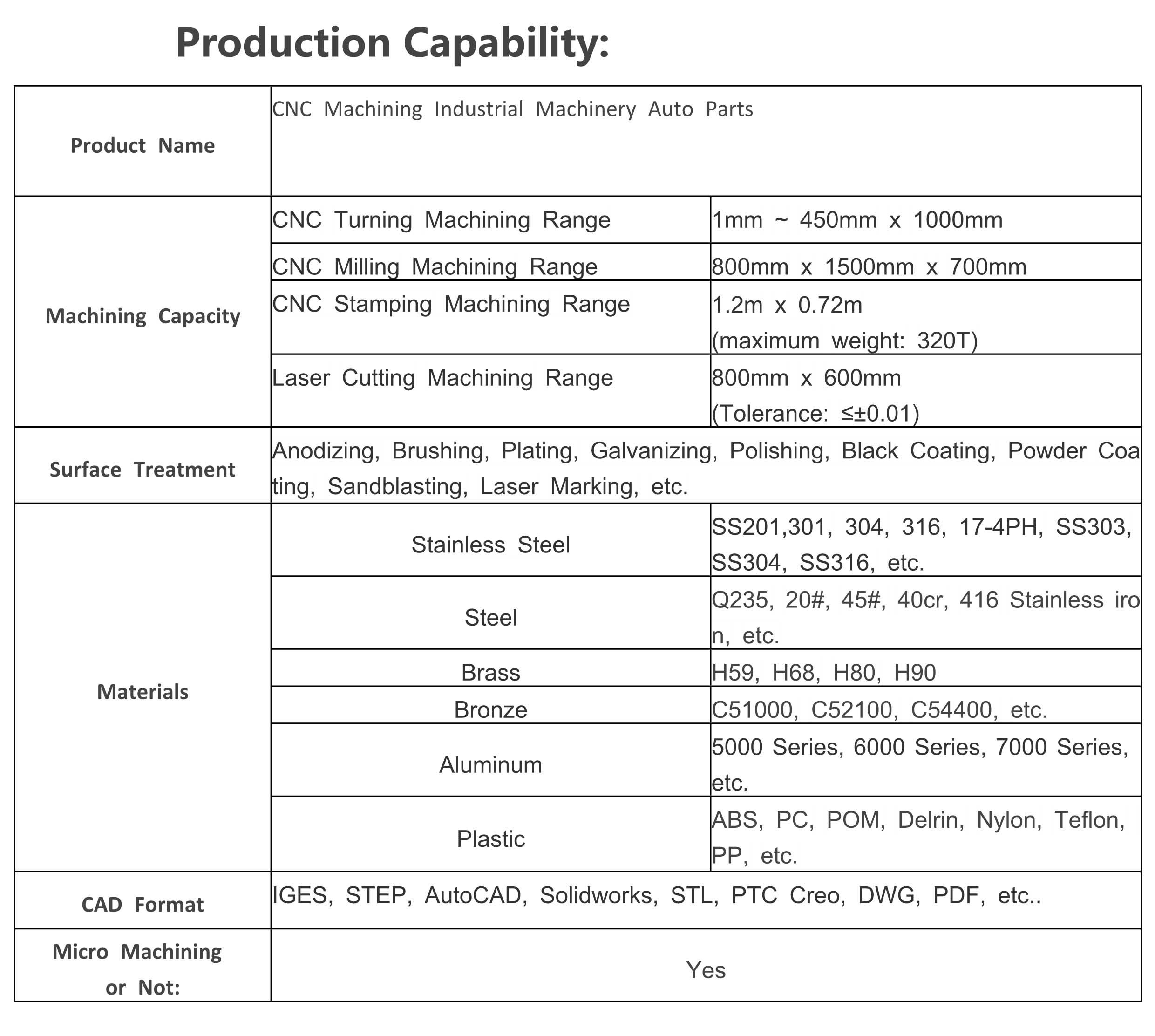

Technical Parameters

Why Choose Us:

Professional quotations within 12 hours

We will keep your information confidential

We are committed to focusing on clients' demand

Latest News:

5 Axis CNC Machining

On the 5-axis machining, the CNC moves while cutting in five angles of the axes simultaneously. This machining process is fast, reliable on designing complex parts, as work is approached in multiple directions.

The 5-axis machining has been adopted widely because of the following:

The set-up is a single one, and this reduces the lead time and better the efficiency

It allows better geometry due to its ability to avoid collision with the tool holder tilting the table or the cutting tool.

Can use shorter tools that are more rigid, some with high spindle speeds rate which is achieved by reducing the load cutting tool.

Pieces don’t pass through different workstation hence errors are reduced, accuracy maintained, and quality is guaranteed.

As we conclude, you are now aware of the various CNC machined aluminum process (milling, drilling, and turning) that unfinished piece of aluminum is taken through until it becomes a complete product. It’s an arduous process that requires experience, accuracy, and powerful machinery. Moreover, these are because of the different aluminum alloy used.

The benefits of aluminum are obvious: fantastic cutting process, the best quality and the demand for a machined aluminum product is on the rise. Industries are snowballing with many specialists to meet your needs, remember to do your research and seek samples to be sure on the quality of the CNC aluminum.

Hot Tags: cnc aluminium machining 4 axis mechanical components, China, manufacturers, suppliers, factory, wholesale, customized, made in China

Send Inquiry